Viledon hydroMaxx enables moisture and snow to permanently roll off

Coalescer prefilters provide gas turbines and compressors with optimum protection against moisture under harsh operating conditions

One of the challenges in air filtration is to combine filter types and filter classes into a tailor-made overall system that is perfectly adapted to the ambient conditions. In humid climates, Viledon coalescer prefilters provide optimum protection for gas turbines and compressors against moisture penetration, thus ensuring plant availability. As two application examples from the USA demonstrate, this applies both to subtropical humid weather conditions characterized by heavy rainfall and to areas where winter storms cause extensive snowfall.

The decisive factor for high operational reliability of turbomachinery under humid climatic conditions is that the prefilter must be capable of effectively separating moisture from the supply air. This allows the downstream filter stages to reliably handle the fine filtration function and avoids an undesirable increase in pressure drop, which is often caused by saturated fine and EPA filters.

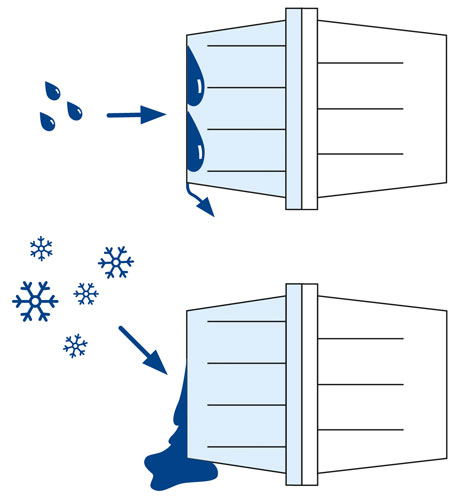

The current top model among coalescer prefilters is the Viledon hydroMaxx pocket filter, which impresses with its excellent droplet separation capacity thanks to the front-side drainage effect. Freudenberg’s proprietary waterrepellent filter medium enables moisture to simply roll off.

Drainage effect and reverse-media concept

Particularly noteworthy here is the reverse-media concept of the filter innovation. This means that the individual filter pockets of the Viledon hydroMaxx face forward in the direction of the airflow. This clever design trick ensures an optimum drainage effect. Unlike traditional pocket filters, water is not retained but is effectively kept off and drained away as if by a protective shield. As the droplets roll off the filter surface, they simultaneously wash away the dust particles that accumulate on the surface of the filter. This self-cleaning process is achieved by the reverse arrangement of the prefilter with a generous “safety distance” to the next filter stage. This in turn ensures that the fine filters remain dry and are able to function reliably.

One practical example of this effect is a power plant in the southern US state of Alabama. Here, Viledon hydroMaxx coalescer filters reliably prevent the sultry humidity of the subtropical air – often polluted by a foggy haze in summer – from reaching the three gas turbines. In recent years, the prefilters have more than proved their effectiveness during several severe thunderstorms and the associated heavy rainfall – with significantly lower pressure drop fluctuations than the previous filter system.

A further plus point is cost efficiency. Whereas the filter mats previously used as prefilters at this power plant had a maximum service life of three months, the Viledon hydroMaxx coalescer filters were still fully functional even after 18 maintenance-free months. This meant that they ensured not only dependable operational reliability in power generation but also low maintenance and repair costs.

Modular clip-on system

The simple handling and great flexibility of the Freudenberg solution are also important for practical applications. Thanks to the modular clip-on system, Viledon hydroMaxx prefilters can be connected to the down-stream filter stage in a space-saving manner to form a single unit. This eliminates the need to invest in an additional filter wall.

In a natural gas power plant in the northeastern state of New York, Viledon coalescer prefilters are proving that they work efficiently and reliably even under extreme weather conditions of a completely different kind. At this power plant, snowstorms made it difficult for the existing filter system to cope. Large quantities of watery powder snow repeatedly clogged the prefilters causing both turbines to automatically reduce their output, resulting in loss of production and reduced revenues. Even under normal operating conditions, the service life of the prefilters in this power plant was a mere two or three months.

Viledon coalescer filters, on the other hand, permanently repel moisture and snowflakes. Each individual filter bag is foamed into a PUR front frame and seamlessly welded to prevent leaks. By way of comparison, the frame of the previous prefilter was made of cardboard. Thanks to the drainage effect, the powder snow rolls off the surface of the pocket filter like drops of water and slides down. When it reaches the ground, the snow melts and the melt-water is drained away in an orderly manner. Thanks to the reverse-media structure, this takes place at a safe distance from the cassette filters of the second filtration stage. The fine filters can now perform their filtration tasks in a dry state, even during heavy snowfall. This ensures plant availability even in adverse weather conditions.

At coastal or offshore locations with salty air and a corresponding risk of corrosion, Viledon filter systems protect turbomachinery just as reliably.

Further information on Viledon coalescer prefilters for power plants can be found here:

Discover Viledon coalescer prefilters for the oil and gas industry: