The service program for the food and beverage industry

Customized service packages for hygienic air quality

Hygienically clean air controls the quality of process air that comes into contact with food and maintains a safe working environment. Optimize your processes and benefit from the economically efficient and energy-efficient solutions provided by our Viledon filterCair air quality consulting and service modules.

What can you do to improve the air hygiene in your production process?

Together with you we will analyse your process conditions and find a solution.

With its numerous modules, Viledon filterCair provides air quality consulting in the food and beverage industry. We have summarized the most important for you.

-

How can I ensure stable, hygienically clean air quality in my ventilation system?

The first step is a comprehensive check of the actual condition of your ventilation system and its specific components, from the supply air duct to the exhaust air duct. Particular emphasis is placed on determining the total number of germs or colonies in the air; this mostly concerns microorganisms. Product contamination can be reduced to a minimum with regular hygiene inspections and airborne germ collections in accordance with VDI 6022-2018. The air filters used must be certified for food and comply with mandatory industry standards.

-

How do I achieve audit security for my ventilation systems in relation to the IFS and BRCGS standards or the ISO 22000/FSSC 22000 standard?

Meaningful and audit-compliant reports are generated for all routine inspections or complete service and maintenance programs for ventilation systems (air handling units) and clean rooms, which form part of an individual Viledon filterCair service contract. Specific inspections and analyses are individually adapted to the needs of your production process.

-

In what way can the ventilation concept influence the shelf life of the product?

The air itself can be a source of contamination. Depending on the expected hygiene risk of the production facility – the EHEDG zone concept is a suitable starting point – the ventilation concept needs to be reviewed and, if necessary, optimized. As well as filter quality, the selection of the appropriate filter efficiency for each filter stage plays an important role. In addition, to reduce the growth of microorganisms, the air quality must be permanently regulated and controlled with regard to temperature and humidity.

-

How can I get my ventilation system checked in terms of hygiene aspects?

We will be pleased to examine your system in accordance with VDI 6022:2018 and carry out an initial hygiene inspection or repeat inspection with airborne germ measurements. All our service specialists are masters or technicians and are qualified according to VDI 6022 Category A. These inspections of the hygiene condition of the ventilation system / air handling units can form part of a Viledon filterCair service contract agreed with you.

-

Am I using the right air filters in my system? Which factors do I need to consider?

When selecting filters, it is crucial that they meet the highest food safety standards and have the required filter classification according to ISO 16890 and EHEDG Doc. 47 recommendations. Filter quality can be measured on the basis of whether filters are microbiologically inactive and suitable for operation at up to 100% relative humidity. They should also be resistant to mechanical stress. Damaged or incorrectly installed air filters represent a weak point for contamination. Depending on whether filters come into direct or indirect contact with food, they have to comply with specific regulations or strict guidelines. Only if the filter quality is certified can you be sure that you are using food-grade air filters.

-

Am I using the correct filter efficiency for each filter stage?

The EHEDG zone concept divides the various areas of a production facility into zones according to the respective hygiene requirements: H (high hygiene risk), M (medium hygiene risk) and B (basic hygiene risk). We use this method of analysis as a basis for recommending a coordinated, multi-stage filter concept with food-compatible air filters of various filter classes and types.

-

How can I reduce the energy consumption of my ventilation system?

We can carry out an energy analysis within the framework of a plant inspection. In the process, we examine individual components for their functionality. An energy analysis precisely measures the current energy consumption. In a more detailed inspection, our technical experts check the complete ventilation system from a cooling capacity > 12 kW according to § 12 EnEv.

We use these values as the basis for creating individual recommendations and optimization proposals to effectively reduce energy consumption over the long term.

-

Can I improve my production process in terms of air exchange and air movement, as recommended in EHEDG Doc. 47?

Within the scope of a flow and overpressure analysis, we are able to visualize the airflow conditions at production and workplaces. This involves a precise measurement of the overpressure, air exchange rates, air speeds and the entire ventilation system in the clean room. Once this process has been completed, you will receive recommendations for optimizing your food factory design. We will also be happy to offer you customized engineering solutions for a plant conversion project.

-

Staff or neighbors are complaining about unpleasant smells. How can I remedy the situation?

The first step is to carry out an on-site analysis. By measuring occupational exposure limits or emission values, we can determine the composition of the air and the associated odors. Based on the results of this analysis, we develop filter or even complete exhaust air concepts that optimize the exhaust air. This may involve additional filter stages or the installation of activated carbon filters, for example. These and other optimizations can form part of the solution. We will be happy to support you wherever clean air for people and machines is required.

Regular hygiene inspections and individual on-site service

Benefit from our all-in-one Viledon filterCair air quality consulting package

Choosing Viledon filterCair also ensures that you guard against inadequate maintenance of air handling units (AHUs) and the filter systems they contain. Malfunctioning or heavily soiled filters support bacterial growth and allow all sorts of contaminants to enter production areas, from pests to fungal spores and microorganisms.

Our Viledon filterCair experts regularly carry out on-site inspections and measurements to ensure a hygienic production environment. This results in high-performance, economical and environmentally friendly management of air quality.

In addition to the modules themselves, Viledon filterCair also offers individual contracts to ensure comprehensive air quality consulting and management services. This includes the provision of all required filters plus customized services.

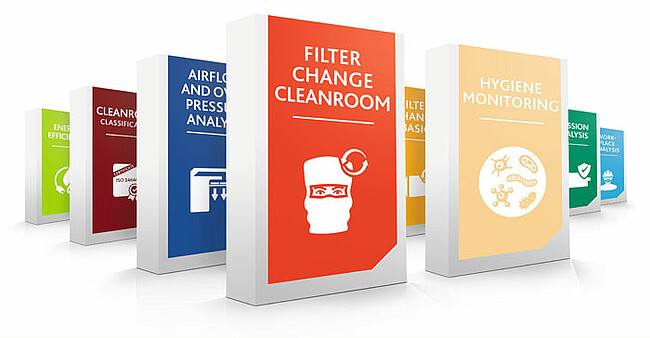

Viledon filterCair service modules

Tailor-made service packages

With our modular Viledon filterCair solutions, we offer you a comprehensive selection of application-specific services and air quality consulting assistance that can also be individually combined with each other. In response to recent events (virus testing program, hygiene monitoring, energy performance inspections), we expand our selection of service modules to include cutting-edge topics.

Module FILTER CHANGE BASIC

Scope of services:

- Planning and organization of filter changes

- Supply of high-quality filter elements for ventilation units

- Thorough cleaning of the filter chamber

- Professional replacement of panel filters, pocket and cassette filters

- Visual assessment of the system components, e. g. inspection of fans, cooling and heating register, drive belts

- Disposal of used filter elements (optional)

- Acceptance report

- Supply of additional high-quality filters as required, such as dust removal cartridges and filter bags

Module FILTER CHANGE CLEANROOM

Scope of services:

- Supply of high-quality HEPA / ULPA filter elements for high hygiene zones and cleanrooms

- Cleaning of the mounting frames

- Professional replacement of HEPA / ULPA filters

- Disposal of used filter elements (optional)

- Leak / impermeability test

- Integrity test

- Airflow determination

- Comprehensive documentation

Module CLEANROOM CLASSIFICATION

Scope of services:

- Cleanroom inspection according to ISO 14644-1 or GMP

- Documentation and certification

Module HYGIENE MONITORING

Scope of services:

- Determination of complete germ counts or complete colony counts in the air, on surfaces and in liquids (bacteria, fungal spores,

viruses …) - Swab test for final control of effective cleaning in critical plants

- Conclusive documentation on the present plant status

- Tests performed to German standard VDI 6022: Hygiene requirements for ventilation and air-conditioning systems and units

Module AIRFLOW AND OVERPRESSURE ANALYSIS

Scope of services:

- Visualization of the flow conditions at production or workplaces

- Detailed video analysis of the airflow conditions

- Checking velocity of airflow and measurement of overpressure

- Temperature and relative humidity measurements

- Checking the ventilation unit (filter audit)

Module EMISSION ANALYSIS

Scope of services:

- Emission value measurement of the exhaust air concentration

- Verification of compliance with emission limit values in accordance with country standard

- Determination of dust mass concentration acc. to EN 13284 (European Standard)

Module WORKPLACE ANALYSIS

Scope of services:

- Review of occupational safety limit values

- Measurement of the maximum workplace concentration

- and statement on PM values

- Determination of air quality

Module ENERGY EFFICIENCY

Scope of services:

- Ventilation consultancy including air volume balances

- Energy efficiency consultancy for air handling units

- Equipment inspection according to § 12 EnEV

- Energetic plant and building inspections according to the German Building Energy Act (GEG) including issuance of an energy certificate

- Volume flow and current consumption measurements on the fan

Benefit from our expertise in the food and beverage industry.

Select and request detailed information.

Discover our products for the food and beverage industry.

Click on details for more information. Technical data and specific product features can be found in the product catalog.

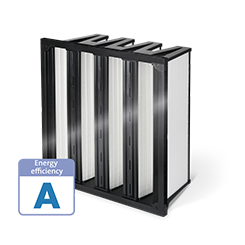

Satisfy the highest requirements for clean air and sterility of filter classes E11 to U15. Reliable protection against particles and microorganisms. The MiniPleat technology ensures a homogeneous media velocity for safe, economical operation.

Excellent filter dependability. Highly stable filter design with dimensionally stable pleat pack withstands extreme loads and ensures maximum operational reliability and a long service life. Water-repellent. Part of the modular clip-on system for 2-in-1 filter solutions.

Robust and extremely dependable in hygienic quality. With water-repelling hybrid synthetic nonwoven media (HSN) suitable for use in damp environments. Ideal for air-conditioning systems.

Energy efficient, combined with high dust holding capacity for energetic optimal operation of ventilation systems. All MVP EE filters achieve energy efficiency class A. Up to 25 % savings in electricity costs and CO2 emissions.

Robust in sustained use, high operational dependability and reliability even in the face of extreme moisture and wet conditions. They enable the energy-efficient operation of air conditioning systems. This translates to energy cost savings and a reduction in CO2 emissions.

With a flexible portfolio that adapts to your needs, we offer the right solution for every dust removal application. High quality and long service life result in low maintenance costs and optimal employee safety. All variants are available as ATEX versions.

Reliable removal of contaminant gases from the supply or recirculating air. The modules are an assembly of Honeycomb (HM) media housed in either a plastic or metallic frame. Easy to install.

Air handling units, fan filter units or tank pressure units ensure the health of employees and protect production processes from contamination. The systematic separation of microorganisms from the supply air prevents contamination via the room or outdoor air.