Highly effective filtering of oil mist

Liquid aerosols cause problems, and not just for health

Cooling lubricants are used in many work steps in metal processing. This is because heat is generated during mechanical processing, which has a negative influence on the service life of tools and machines. Cooling lubricants counteract this and at the same time ensure that the surface of the workpiece is handled more cleanly. Despite these positive aspects, cooling lubricants pose a problem in the area of work and process safety. During use, they produce very finely distributed aerosols that consist, among other things, of dust particles and in particular oily droplets that pollute the air and thus people and machines.

Air polluted by oil mist causes problems

Contaminated air creates serious problems that pose a risk to people, the environment and machinery.

Work and environmental safety

The most common problems include:

- Respiratory problems, skin and eye irritation

- Increased risk of slipping and accidents when oil settles on the floor

- Environmental problems with uncontrolled run-off of oils and emulsions

Process safety

The most common problems include:

- Dirty machinery and equipment

- Electronic components become disturbed or damaged

- Ventilation system function is impaired (room air deteriorates)

- Fire and explosion hazards

The Viledon Solutions – effective and versatile

Precisely tailored concept for maximum filtration effect

In these applications, it is usual to use 3-4 stage filter system, which is specifically adapted to the general conditions on site. By using coalescing separators of various size levels, the air is effectively cleaned of oily vapors. Similarly, Viledon filters can be used in all stages downstream of a pre-separator, or as an additional safety stage downstream of electrostatic precipitators.

The Viledon solutions for the filtration of oil mist are suitable for all practical requirements likely to be encountered.

The filters work reliably for:

- centralized extraction systems with several machining centers

- decentralized extraction systems at individual machining centers

- blow-off benches

- room air extraction

Your benefits:

- High effectiveness by field-proven Viledon filter solutions

- Longer filter life through unique nonwovens and manufacturing processes

- Reduced energy consumption and lower total costs

- Plannable and individual service offers

Benefit from our specialized expertise in oil mist filtration

Select and request detailed information.

Discover our products for oil mist filtration

Click details for more information. Technical data and specific product features can be found in the product catalog.

Robust in sustained use, high operational dependability and reliability even in the face of extreme moisture and wet conditions. They enable the energy-efficient operation of air conditioning systems. This translates to energy cost savings and a reduction in CO2 emissions.

Optimal protection against penetrating water and salt – offshore or in coastal regions and locations with high humidity. Special drainage properties prevent the passage of water droplets into subsequent filter stages.

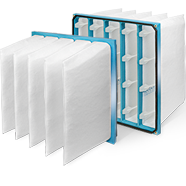

Excellent filter dependability. Highly stable filter design with dimensionally stable pleat pack withstands extreme loads and ensures maximum operational reliability and a long service life. Water-repellent. Part of the modular clip-on system for 2-in-1 filter solutions.

Final filter stage for critical substances such as oil mist, coolants and aerosols. Also applicable as safety filters for asbestos, quartz and heavy metals.