Smart control keeps corrosion at bay

Freudenberg's ChemWatch S system ensures real time air quality evaluation to better manage operation and equipment

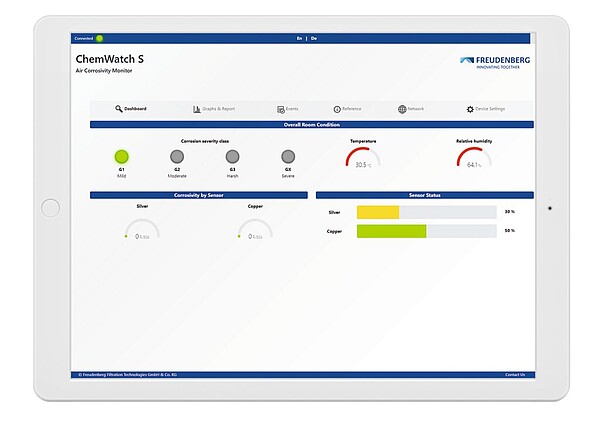

With the ChemWatch S Air Corrosivity Monitor, Freudenberg introduces a new generation of its corrosion monitoring system. It helps to limit the risks of corro-sion damage to electronic components and metal surfaces by monitoring air quality in real time. Intuitive to use and compatible with a wide range of applications, maintaining clean air and a safe working environment has never been smarter

Metal surfaces and electrical components are more sensitive than meet the eye. Especially in industrial environments such as the pulp and paper production, petroleum and chemical processes, data centers, metallurgical or steel furnaces or enclosed spaces like server rooms, corrosive fumes and gases can cause severe damage to electrical equipment. As a result, productivity suffers, maintenance costs increase and unplanned downtime becomes inevitable. One option is to install gas phase filters that reduce the contaminants in the air. In addition, corrosion monitoring systems offer an effective way to ensure conduc-tivity by providing early detection of leaks or the gas phase filter’s end of life.

Monitoring of corrosion severity levels G1 to GX

Freudenberg's ChemWatch S provides reliable information on the risk of corrosion from acid gases by continuously monitoring the temperature, relative humidity, and corrosion rates of the air via four state-of-the-art sensors. Compliant with ANSI / ISA 71.04-2013, it aids in early detection of gas leaks and sources of interference. This enables operators to take prompt action to protect sensitive components and, most importantly, ensure a safe working environment.

Easy to set up and manage, the compact and durable ChemWatch S comes with an intuitive, detailed dashboard and supports all major operating systems (iOS, Android, Windows, Linux) via ethernet or wireless connection. Measurement data can be easily exported from the dashboard in XLSX or PDF format or via Modbus connection. As operators can access data from the dashboard anytime and anywhere, there is no need for an additional display on the monitor, making the ChemWatch S both more robust and less expensive than previous sensor systems.

Uploading data in real time

But size does not compromise performance: an internal memory provides more than two years of data recording, while cloud-based data transfer via MQTT enables real-time data transmission. With optimized interface compatibility, data from multiple devices and process control systems can be easily consolidated and analyzed via the cloud. In addition, ChemWatch S supports and integrates seamlessly with Azure Cloud and other Microsoft applications, providing maximum reliability and data control from a single source.

The spoilt for choice

If it is preferred to have everything directly in view and use an analog data output, the regular ChemWatch is a good choice. It provides a color display on the front. The shape of a chart shows whether the contaminant gas concentration is in the “green zone” and how it has developed over time. Also, the regular ChemWatch has an integrated removable data storage unit. This can be read out at another non-sensitive location if data transfer at the device location is not possible for security reasons.