Adhering to hygiene requirements and protecting food with HACCP

HACCP stands for Hazard Analysis & Critical Control Points. This internationally valid control system for food safety is intended to prevent health risks. It includes the description of all process sequences, the identification of risks in all process steps and the classification of the probability of occurrence of these risks. It also determines limit values and measures to be taken in the event of deviation from these values. The HACCP concept has been listed in the Codex Alimentarius since 1992. It is published by the Food and Agriculture Organisation (FAO) and the World Health Organisation (WHO) and contains standards for food safety and food product quality for food producers worldwide. In the meantime, the HACCP concept is obligatory in many countries of the world according to EU Regulation (EC) No. 852/2004. Due to the varying requirements, HACCP is individually for each company. There is no universally valid standard concept for HACCP.

What are the goals of HACCP?

Product safety is the top priority in the production of food and beverages. Compliance with hygiene standards is of great importance in this respect. Even minor impurities can lead to contamination and endanger the health of consumers. HACCP aims to ensure quality in all food production processes and to eliminate health hazards or at least reduce them to a minimum. Even though the system was developed and is used for the food industry, other areas such as catering or clinics can also benefit from putting it into practice.

Who is the HACCP concept relevant for?

Manufacturers of beverages or foodstuffs have a special duty of care. HACCP is relevant for all companies that commercially produce, handle and market food. This includes, for example, the preparation, processing, measuring, filling, packaging, storage and transport of food. These companies are responsible for reliably ensuring the safety of foodstuffs in their working environment. They are legally liable for this. The HACCP concept does not apply to the primary production of plant or animal foods that are not further processed or prepared (as in agriculture). Examples of where HACCP is relevant include:

• Dairy products

• Convenience food

• Meat processing

• Baked goods

• Confectionery

• Fruit/vegetable processing

Hazards posed by product contamination in food manufacturing

In the food industry and in food-producing plants, conditions are ideal for the growth of microorganisms. These are not fundamentally harmful. Some microorganisms are even useful and are used in the production of food. These include, for example, lactic acid bacteria in dairy products or yeast used in beer brewing.

However, these microorganisms must be kept apart from those that are capable of spoiling food and causing diseases in the human organism. If the conditions are favorable, these germs can multiply into hundreds of millions within a short period of time. When bacteria or viruses contaminate food and beverages, it is no longer safe to consume them. The human immune system of healthy people can often still cope with a small number of germs. Large quantities, however, can lead to serious illnesses such as food poisoning. A product recall is often associated with high costs and damage to the company’s image. This is why a precise hygiene concept is essential for the safe production of food.

The seven steps of the HACCP concept

Every area in which the production cycle takes place must be critically analyzed to identify all potential sources of contamination. An HACCP concept includes the following seven steps:

- Hazard analysis: Identification of potential hazards in food production at all stages of production. Establishing measures to counteract the hazards.

- Identification of critical control points (CCPs): Determining critical control points that are associated with risks, for example, an incorrect storage temperature.

- Definition of limit values: Setting limit values in the area of the critical control points (for example, cooling temperatures).

- Setting up monitoring measures: Establishment of actions to ensure compliance with the limit values from point 3 and monitoring of the critical control points from point 2.

- Definition of corrective measures in the event of deviations: Determining measures to be taken if the defined limit values are exceeded. If limit values are exceeded, the foodstuffs concerned should under no circumstances end up with the consumer.

- Review and control of the measures: The HACCP concept must be regularly reviewed and, if necessary, adapted so as to ensure safe food production in the long term.

- Documentation: To ensure traceability and transparency, all measures and corrections must be documented, for example the data on the control points, limit values, test methods and the procedures in the event of deviations.

What are the advantages of HACCP?

HACCP certification offers many advantages. HACCP improves food safety to protect consumers from health risks. With an HACCP concept, you show your customers and business partners that you comply with the hygienic safety measures in your beverage or food production and thus act as a future-proof company. A certificate such as by the International Featured Standard (IFS) Food as well as by BRCGS (Global Standard for Food Safety of the British Retail Federation) is proof of compliance with your duty of care. Companies that implement the HACCP concept have better control of their product inventory. HACCP can help reduce product recalls and liability risks, which can help protect against significant financial losses.

Hygienic clean air

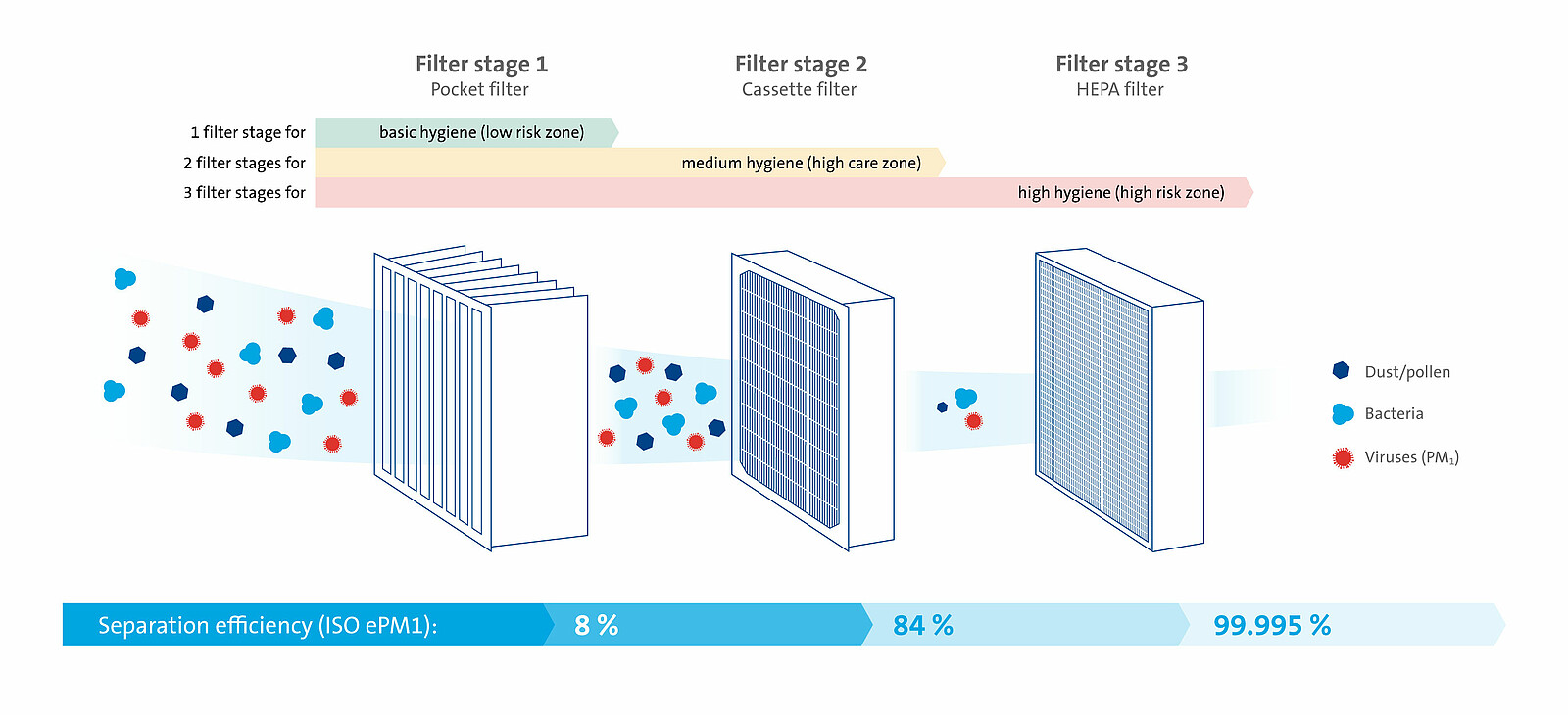

To ensure the safe production of food and beverages, a high level of air quality is essential. Modern, optimally maintained and hygienically perfect ventilation systems with high-performance air filters effectively combat product contamination and protect employees against infection. Filters used in food production must meet the highest industry standards. The individual areas in food and beverage production each require different levels of hygiene. For this reason, two- or three-stage filter systems are ideal for meeting the highest hygiene standards and fulfilling HACCP guidelines.

According to EHEDG Guideline 47, installation of at least a 2-stage filter system is advisable in production areas with a medium hygiene risk, and a 3-stage filter system in areas with a high hygiene risk. Pocket filters (filter stage 1) act as prefilters to remove large particles such as dust and pollen from the supply and recirculated air. Cassette filters (filter stage 2) are optimal for dealing with particulate matter and microorganisms thanks to their high dust holding capacity. HEPA filters (filter stage 3) remove over 99.995 % of the remaining particles, germs and viruses (including coronaviruses) from the air.

Your contact for effective hygiene management

Freudenberg Filtration Technologies would be pleased to support you in optimizing your hygiene management process and complying with HACCP guidelines. We carry out hygiene inspections, hygiene controls and airborne germ collections according to VDI 6022-2018. We base the design of ventilation systems on the EHEDG guidelines and the EHEDG zone concept and adapt it to the specific conditions of food production. We determine the total microbial count of microorganisms in the air, on surfaces or in liquids and measure air velocities and overpressure. Our services also include filter monitoring and air filter replacement. You can rely on our more than 60 years of experience in ventilation and filtration technology.