Discover filtration solutions for air pollution control

Benefit from Freudenberg’s comprehensive expertise

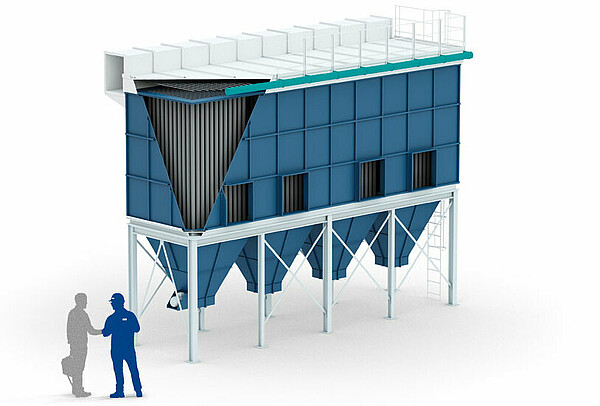

During the processing or production of raw materials and workpieces, minute dust and oil particles enter the ambient air. These aerosols can be harmful and thus pose a problem with regard to work and process safety. In the form of powders, dusts can also be the product itself. The task is therefore to meet the individual requirements with suitable filter systems so as to protect people and optimize processes.

In the area of air pollution control, we specialize in the filtration of aerosols from the air generated by processes to ensure safe working and environmental conditions. When recovering powdery products or dusts in silos, the focus is on maximum efficiency and operational safety.

Why the topic of air pollution control is also important for you

Aerosols as a by-product or production good

Smoke, dust or oily mist are often an undesirable by-product of manufacturing processes. At the same time, in some industries these can also represent the actual production material.

If dusts are the product itself, it is extremely important to safely and efficiently separate the valuable production material from the airflow for further processing.

The right solution for every requirement: Viledon filter systems are specially developed to meet the wide-ranging requirements of dust removal and emission control, and meet the most stringent controls.

Competence Areas

Problematic aerosols arise throughout a wide range of industries and industrial processes

Viledon Filter Service: Optimization, maintenance and servicing of your filter system

For maximum efficiency and operational reliability

Viledon filter service has a filter management system uniquely customized to your needs to offer you the maximum benefits of high-quality Viledon air filters. From routine inspections to a complete service and maintenance program for your filtration system to achieve maximum efficiency.

Benefit from our specialized expertise in air pollution control

Select and request detailed information.

Discover our products for air pollution control.

Click details for more information. Technical data and specific product features can be found in the product catalog.

With a flexible portfolio that adapts to your needs, we offer the right solution for every dust removal application. High quality and long service life result in low maintenance costs and optimal employee safety. All variants are available as ATEX versions.

Excellent filter dependability. Highly stable filter design with dimensionally stable pleat pack withstands extreme loads and ensures maximum operational reliability and a long service life. Water-repellent. Part of the modular clip-on system for 2-in-1 filter solutions.

Final filter stage for critical substances such as oil mist, coolants and aerosols. Also applicable as safety filters for asbestos, quartz and heavy metals.