Discover our filtration solutions for the food and beverage industry

Benefit from Freudenberg expertise now

Reliable protection with the EHEDG zone concept

Food and beverage production – select the right filter for the respective hygiene zone

In food and beverage production, even minimal contaminant levels in the air can lead to contamination of the entire food production. The result: Reduced shelf life or even worse consequences. Producers utilize a zone concept in order to protect foods and beverages during every production process.

The zone concept classifies the individual production areas by their hygiene risk and specifies the hygiene level that must be achieved in each production step. The required purity level varies depending on the product being made and the stage of production.

Multi-stage filter systems from Freudenberg reliably filter particles and microorganisms from the air and have proven themselves ideal for compliance with the strict hygiene requirements.

How to ensure hygienic air quality in food and beverage production

Learn more about the key factors for cleanroom production zones

Understanding the zones

Depending on the hygiene requirements, the various zones of a production facility are categorized as high (high-risk), medium (high-care) or basic (low risk).

Basic hygiene (low risk) zone

Control of contaminant sources on a low level

These zones require only a basic level of hygiene. Examples include areas used for storing pre-packaged goods.

ProductsMedium hygiene

(high care) zone

Reduce the creation of hazardous sources

The objective here is to directly control or reduce the potential sources of contaminants in order to protect food production from contamination.

ProductsHigh hygiene

(high risk) zone

Effectively control of contamination hazards

The highest level of hygiene must be maintained in these enclosed areas for the processing and packaging of products. All dangers leading to food contamination or microbial growth must be effectively controlled or prevented.

ProductsSatisfying the highest hygiene demands

100% audit compliant for food

In the food industry, a hygienic production environment is essential for smooth processes as well as compliance with statutory requirements. With controlled and monitored air quality (temperature, humidity and particle concentration), product contamination can be reliably minimized. In addition, the clean ambient air contributes to the protection and comfort of the employees. Take no chances: with filtration solutions for the food and beverage industry that meet the most stringent requirements. Additional guidelines and standards also exist to ensure that the stringent hygiene requirements for the production processes of the food and beverage industry are met.

Clean rooms capable of achieving an extremely low particle concentration in the air are increasingly common in practice. For determining the purity level of a room, there are two established classification systems to choose from: EN ISO 14644-1 and the "Good Manufacturing Practice” guidelines (GMP).

There are also a number of important rules and standards in place to ensure that the stringent hygiene requirements on the production processes of the food and beverage industry are met.

In our download area, you will find detailed information about our technologies.

Protecting the food we eat

Hygienic air filtration solutions for the food and beverage industry

Viledon filters are food-safe

Our certificates document fulfillment of the regulations that apply to the respective filter tests. Request the certificate required for your application here.

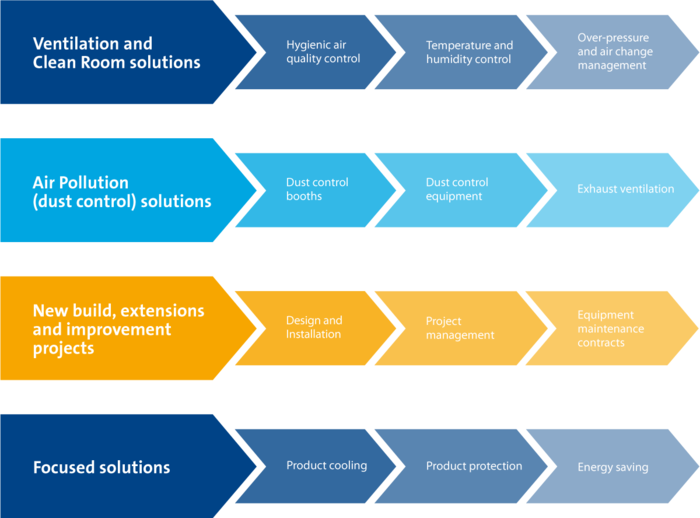

Are you planning the modification or installation of a ventilation or environmental control system?

We support you with precise planning and customer-specific solutions

Only a ventilation system that is precisely tailored to your specific requirements can exploit the full potential in terms of hygiene performance and energy efficiency. This is why we support your modification or installation project with a comprehensive development and installation program that can be specially customized to your needs.

We individually plan and carry out any plant construction project in accordance with the respective process requirements for food production. This ensures that the air quality we supply meets the requirements of food manufacturing standards as required by your customer and relevant quality standards organization.

This might also interest you: engineering of filtration systems for efficient wastewater treatment

Customized air quality management with Viledon filterCair

Improved safety in all production steps for the food & beverage industry

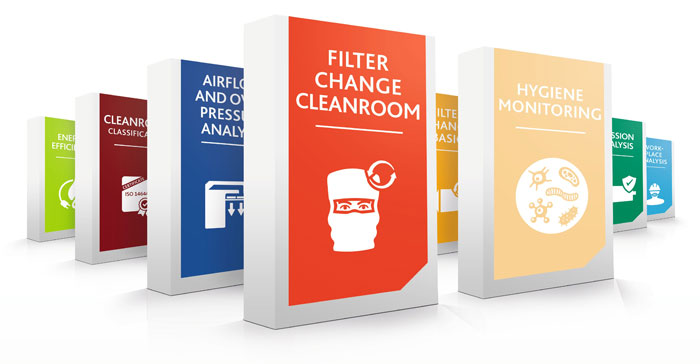

Viledon filterCair is a filter management system uniquely customized to your needs .

With individual service contracts or various service modules which can be individually combined with each other, we offer you a comprehensive range of services to meet your stringent industry hygiene requirements: from routine inspections to a complete service and maintenance program for ventilation and dust removal systems as well as cleanrooms. In this way, we guarantee the professional maintenance of your ventilation system and the filter installation, thus ensuring optimum reliability of your ventilation system. Preventing the build-up of moisture and contaminants, which can support bacterial and fungal growth and threaten the security of your production and packaging areas.

Optimise your processes and benefit from the economically efficient and energy-efficient solutions provided by our Viledon filterCair service modules.

How efficient is your filtration system?

Find the optimal filter solution for your plant with e.FFECT based on ISO 16890

Standardized systems for supply air filtration are frequently inefficient and do not make full use of their potential for optimization. The more specifically filter systems are customized to the respective ambient conditions and plant requirements, the greater performance and reliability they achieve.

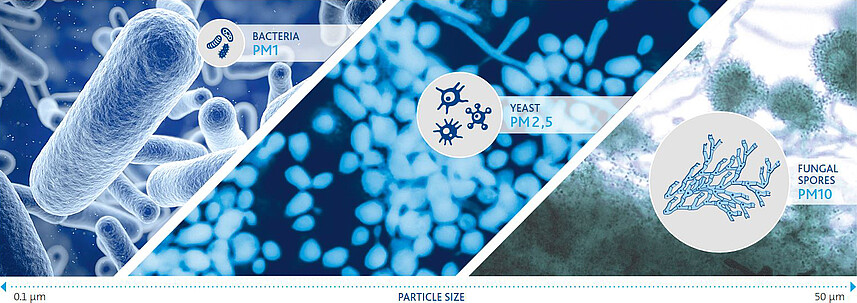

Our experts work with you to develop the best filter solution for your plant on the basis of the testing standard ISO 16890. In the filter evaluation, typical urban and rural particle size distributions are considered based on the particulate matter fractions PM1, PM2,5 and PM10, and filter arrestance efficiencies are determined accordingly.

Learn more about ISO 16890

With e.FFECT, the electronic Freudenberg Filter Efficiency Calculation Tool, calculating the optimal filter solution is extremely simple. The local ambient conditions and specific process requirements enter directly into the calculation. Multi-stage filter systems can then be objectively compared. This simplifies the selection of the best filter concept for your needs.

Exemplary particle classification to PM fractions for food and beverage

Exemplary particle classification to PM fractions for food and beverage

Benefit from an optimal filtration solution with e.FFECT

Request detailed information.

Discover our products for the food and beverage industry.

Click on details for more information. Technical data and specific product features can be found in the product catalog.

Satisfy the highest requirements for clean air and sterility of filter classes E11 to U15. Reliable protection against particles and microorganisms. The MiniPleat technology ensures a homogeneous media velocity for safe, economical operation.

The technically stable and engineered design of the MaxiPleat series offers continuous reliable operation for even the most extreme conditions. With a hydrophobic coating, a patented thermal embossing process, and leak-proof casting, these filters provide dependability with cost efficiency.

Energy efficient, combined with high dust holding capacity for energetic optimal operation of ventilation systems. All MVP EE filters achieve energy efficiency class A. Up to 25 % savings in electricity costs and CO2 emissions.

Filter media that is progressively structured of high-performance nonwovens, produced from non-breaking fibers ensures high durability and long useful lifetime.

Ideal for upgrading of typical systems, these long lifespan filters operate even under extreme operating conditions. Especially effective in the separation of abrasive or chemically aggressive dusts. For cost efficiency, the service life can be extended by washing.

Viledon gas phase filtration solutions are designed to protect sensitive components and systems against corrosion.

Air handling units, fan filter units or tank pressure units ensure the health of employees and protect production processes from contamination. The systematic separation of microorganisms from the supply air prevents contamination via the room or outdoor air.

![[Translate to English (US):] Effective air filtration protects food production processes from germs and viruses [Translate to English (US):] Effective air filtration protects food production processes from germs and viruses](/media/_processed_/9/2/csm_FFT_Virus_Produktion_gross_9a27b3e013.jpg)