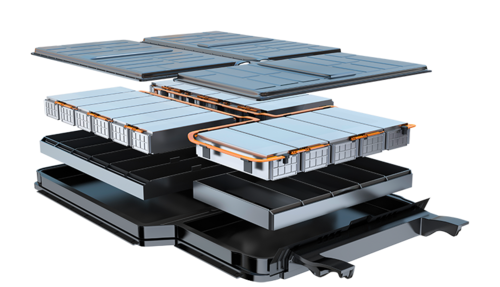

Custom-made air filtration solutions for battery manufacturing

Air filtration is essential to the lithium-ion battery manufacturing process. It drives product quality, process reliability and production performance, contributes to occupational safety and protects the environment. Operating robust air filtration systems is a proactive measure that not only improves the competitiveness of battery manufacturers, but also drives the development of innovative energy storage solutions for the future. Backed by our extensive industry knowledge and close collaboration with our sister company XALT Energy, a manufacturer of storage solutions, we help battery line manufacturers and operators realize next-generation filtration systems.

The most critical air quality challenges in lithium-ion battery manufacturing

From mixing to pack assembly - discover filtration in the battery manufacturing process

Each process step in the production of lithium-ion batteries has its own specific air quality and filtration requirements. Let us advise you and provide you with services and a complete range of product solutions that simply fit. Powerful. Energy-efficient. Process-safe. For you as a battery production operator or plant manufacturer, this gives you the security of being in the best possible position when it comes to air filtration.

For reliable and worry-free air treatment

Supporting development and design phases of HVAC systems

Individual planning, in-depth consulting and tailormade filter elements for your HVAC design.

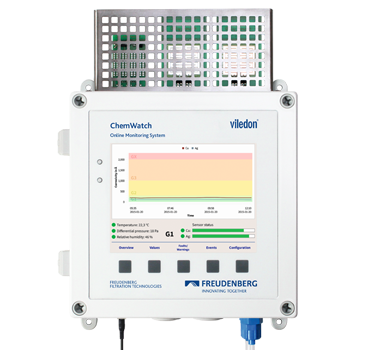

Monitoring air quality, corrosion risks and system conditions

Intuitive online monitoring that provides valuable insight into air quality and system conditions.

Facilitating filter unit maintenance

Proven services for filter replacement, workplace and defect analysis. All-in-one air quality management package.

Minimizing particle ingress and contamination risks

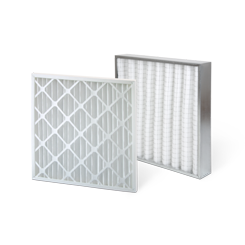

Powerful high temperature and HEPA filters, reliable pocket and cassette filters, and other solutions such as gas phase pellets keep the air clean at every stage of the process.

ATEX: Ensuring safety in explosive atmospheres

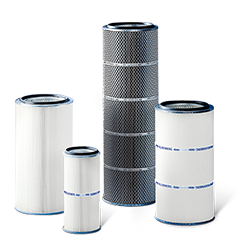

ATEX-approved filter elements such as our filter cartridges, pocket filters, and cassette filters offer great safety for critical areas including coating mixing or solvent recovery.

Durable and long-lasting filter equipment

Air filters with specific and tailor-made resistance to high process temperatures or chemical attack of the typical and critical organic solvents (e.g. NMP).

Protecting employees

Filtration of harmful gases and substances such as solvents or acidic gases from air with gas phase filtration equipment to provide a high level of workplace safety.

Protecting the environment

Filters in facilities to remove solvents and acidic gases in exhaust air for less pollution and energy-efficient systems for fewer emissions.

Protecting processes and electronics

Adsorption of corrosive gases, corrosion protection and dust removal to prevent short circuits, damage to electronic components and production downtimes.

Air filtration in battery manufacturing –

what to keep in mind

Not every production process requires cleanroom conditions (ISO 14644)

Freudenberg filter elements and systems are particularly durable, reliable and energy-efficient

Systematic digital monitoring with Viledon Process View gives you additional efficiency and safety

Minimize your efforts and overall expenses with product supply and services from a single source

Contact us

Discover our products for battery manufacturing

Find technical data and specific product features in the product catalog

Versatility for longer service lives: for use in prefiltration of ventilation and air-conditioning systems to protect downstream fine filters and as edrizzi post-filters for separation of overspray.

Filter media that is progressively structured of high-performance nonwovens, produced from non-breaking fibers ensures high durability and long useful lifetime.

The technically stable and engineered design of the MaxiPleat series offers continuous reliable operation for even the most extreme conditions. With a hydrophobic coating, a patented thermal embossing process, and leak-proof casting, these filters provide dependability with cost efficiency.

The best choice for air filtration at temperatures above 100°C up to a maximum of 385 °C. The silicone-free filter elements are suited for extreme and stringent requirements for air purity, process dependability, all with cost-efficiency.

Even at high flow rates, HEPA filters ensure optimum flow with low pressure differences. Essential in certain process steps of battery production.

Ideal for upgrading of typical systems, these long lifespan filters operate even under extreme operating conditions. Especially effective in the separation of abrasive or chemically aggressive dusts. For cost efficiency, the service life can be extended by washing.

Viledon gas phase filtration solutions are designed to protect sensitive components and systems against corrosion.

Measures and monitors the corrosivity of air in rooms via copper and silver sensors. The only online monitoring system with a large color display for clear visibility at a glance.

![[Translate to English (US):] Battery manufacturing [Translate to English (US):] Battery manufacturing](/media/_processed_/d/5/csm_banner-battery-manufacturing_d564a72c8f.jpg)

![[Translate to English (US):] Our services for plant manufacturers [Translate to English (US):] Our services for plant manufacturers](/media/_processed_/2/e/csm_oem-battery-manufacturing_2e45351678.jpg)

![[Translate to English (US):] Our services for operators [Translate to English (US):] Our services for operators](/media/_processed_/c/6/csm_operators-battery-manufacturing_d3725f2515.jpg)

![[Translate to English (US):] Battery manufacturing process: Mixing [Translate to English (US):] Battery manufacturing process: Mixing](/media/_processed_/4/f/csm_factory-machines-01-cut_64c6165cc3.png)

![[Translate to English (US):] Battery manufacturing process: Coating [Translate to English (US):] Battery manufacturing process: Coating](/media/_processed_/f/1/csm_factory-machines-02-cut_4879704a56.png)

![[Translate to English (US):] Battery manufacturing process: Drying line [Translate to English (US):] Battery manufacturing process: Drying line](/media/_processed_/e/9/csm_factory-machines-03-cut_01_028ebc349a.png)

![[Translate to English (US):] Battery manufacturing process: Slitting converting [Translate to English (US):] Battery manufacturing process: Slitting converting](/media/_processed_/7/c/csm_factory-machines-04-cut_fbf21638b6.png)

![[Translate to English (US):] Battery manufacturing process: Stapling vacuum drying [Translate to English (US):] Battery manufacturing process: Stapling vacuum drying](/media/_processed_/a/c/csm_factory-machines-05-cut_ffc2bf76d6.png)

![[Translate to English (US):] Battery manufacturing process: Cell assembly [Translate to English (US):] Battery manufacturing process: Cell assembly](/media/_processed_/b/4/csm_factory-machines-06-cut_9a752cf2e1.png)

![[Translate to English (US):] Battery manufacturing process: Formation [Translate to English (US):] Battery manufacturing process: Formation](/media/_processed_/2/1/csm_factory-machines-07-cut_ad25ee766f.png)

![[Translate to English (US):] Battery manufacturing process: Pack assembly [Translate to English (US):] Battery manufacturing process: Pack assembly](/media/_processed_/6/f/csm_factory-machines-08-cut_0fd07685d1.png)