Discover our solutions for gas turbines and compressors

Benefit from Freudenberg expertise now

Benefit from our specialized expertise in gas turbines and compressors.

Select and request detailed information.

The new classification system to ISO 29461-1

makes filter selection for turbomachinery easier

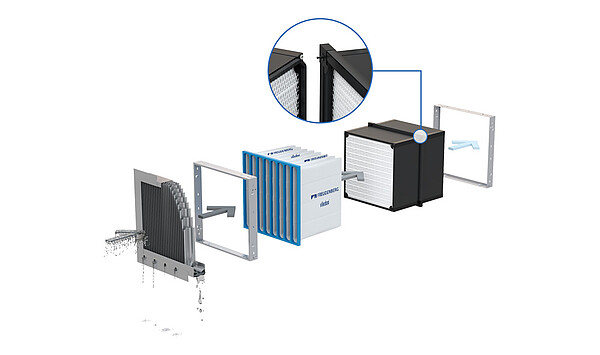

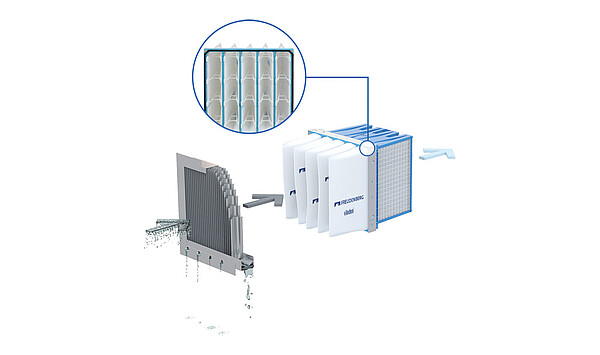

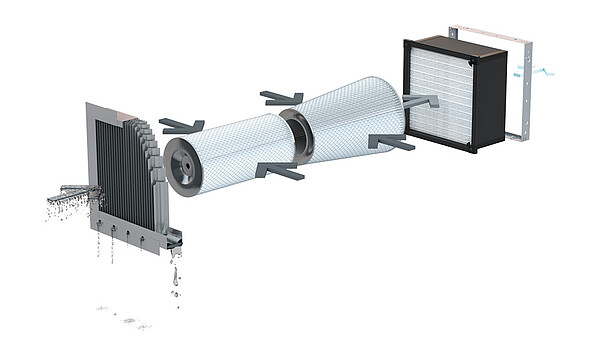

Multi-stage filtration concepts

Performance-optimized for your individual requirements

Multi-stage filtration systems ensure effective filtration and increased protection of turbines and compressors. Fouling damage is kept to a minimum, unplanned downtimes can be avoided, general maintenance costs are reduced, and optimal turbine efficiency can be achieved.

In a two-stage system, an upstream pocket filter protects the cassette filter of the final stage. In a three-stage system, an additional downstream cassette filter stage is added. This can provide filtration levels by EPA standard. The selection of filters for each stage depends primarily on the environmental conditions around the plant, as well as on any space limitations. This is how we provide customized solutions for you.

Discover our selection of tried and tested multi-stage filter systems for your custom-tailored solution for gas turbines and compressors

Achieve maximum filtration performance with a simplified plant upgrade using the modular clip-on system.

Availability is key in the power industry

Learn more about the strengths of eMaxx cassette filters

![[Translate to English (US):] Freudenberg Filtration Technologies e.FFECT [Translate to English (US):] Freudenberg Filtration Technologies e.FFECT](/media/_processed_/b/1/csm_freudenberg-filtration-technologies-effect-logo-wide_6ea4dbd9b2.jpg)

How efficient is your filtration system?

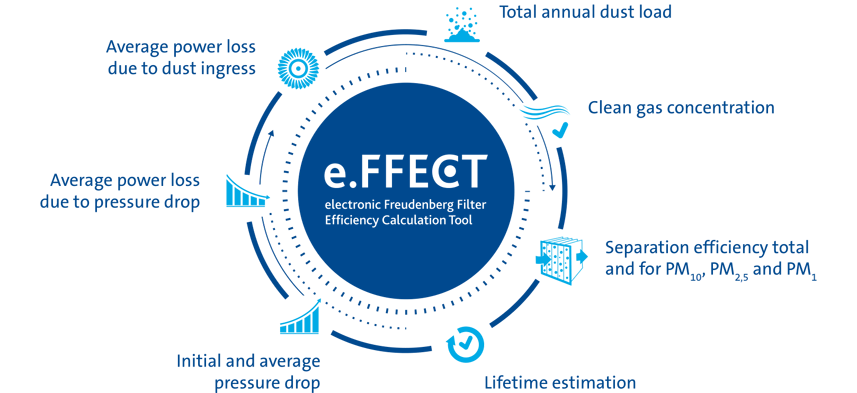

e.FFECT – Digital Algorithm for Optimal Filtration

Ambient conditions vary by plant. From deserts, urban areas, or coastal districts; Sandstorms, humidity, or salty air. These conditions cause corrosion damage to equipment if not properly suited with the correct filtration system. Standardized filtration solutions sometimes do not take into account all variables, and therefore are not designed to cope with specific requirements.

e.FFECT is the solution. A proprietary software tool that optimizes filter systems and tailors them to specific environmental conditions.

With e.FFECT, the electronic Freudenberg Filter Efficiency Calculation Tool, calculating the optimal filter solution is extremely simple. The local ambient conditions and specific process requirements enter directly into the calculation. Multi-stage filter systems can then be objectively compared. This simplifies the selection of the best filter concept for your needs.

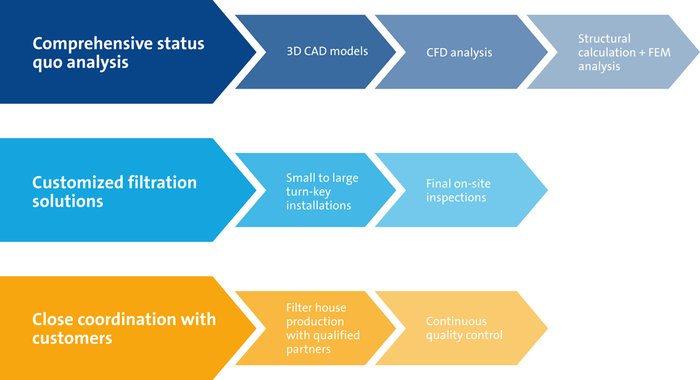

Individually developed, precisely planned

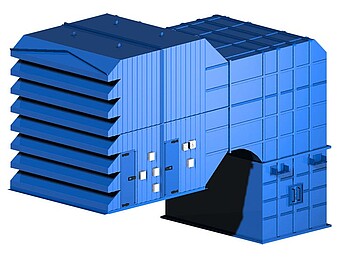

Conversions and construction of new intake air systems with Viledon Engineering

Whether conversion or new construction – implement your individually customized system solution anywhere in the world with the comprehensive engineering development and installation services of Freudenberg. Filter systems achieve maximum performance when they are adapted to the specific requirements. For this reason, we offer you individual service packages for planning and installation. From on-site analysis, consulting, system design and order processing to training and after-sales service – discover the most efficient solution for your new gas turbine and compressor air intake system with the help of our team of technicians.

In our download area, you will find detailed information about our technologies.

Maximizing the efficiency of gas turbines and compressors

Customized and powerful filtration solutions for clean air

Discover our products for gas turbines and compressors.

Click on details for more information. Technical data and specific product features can be found in the product catalog.

spiderMaxx stands for a generation of casette filters that sets standards in terms of stability and torsional rigidity thanks to the innovative filter frame design. Even under high load, the casette filters provide peak performance for efficient energy generation and minimal downtime in power plants.

The high mechanical strength of the material offers dimensional stability throughout operational lifetime, even when handling large air volumes.

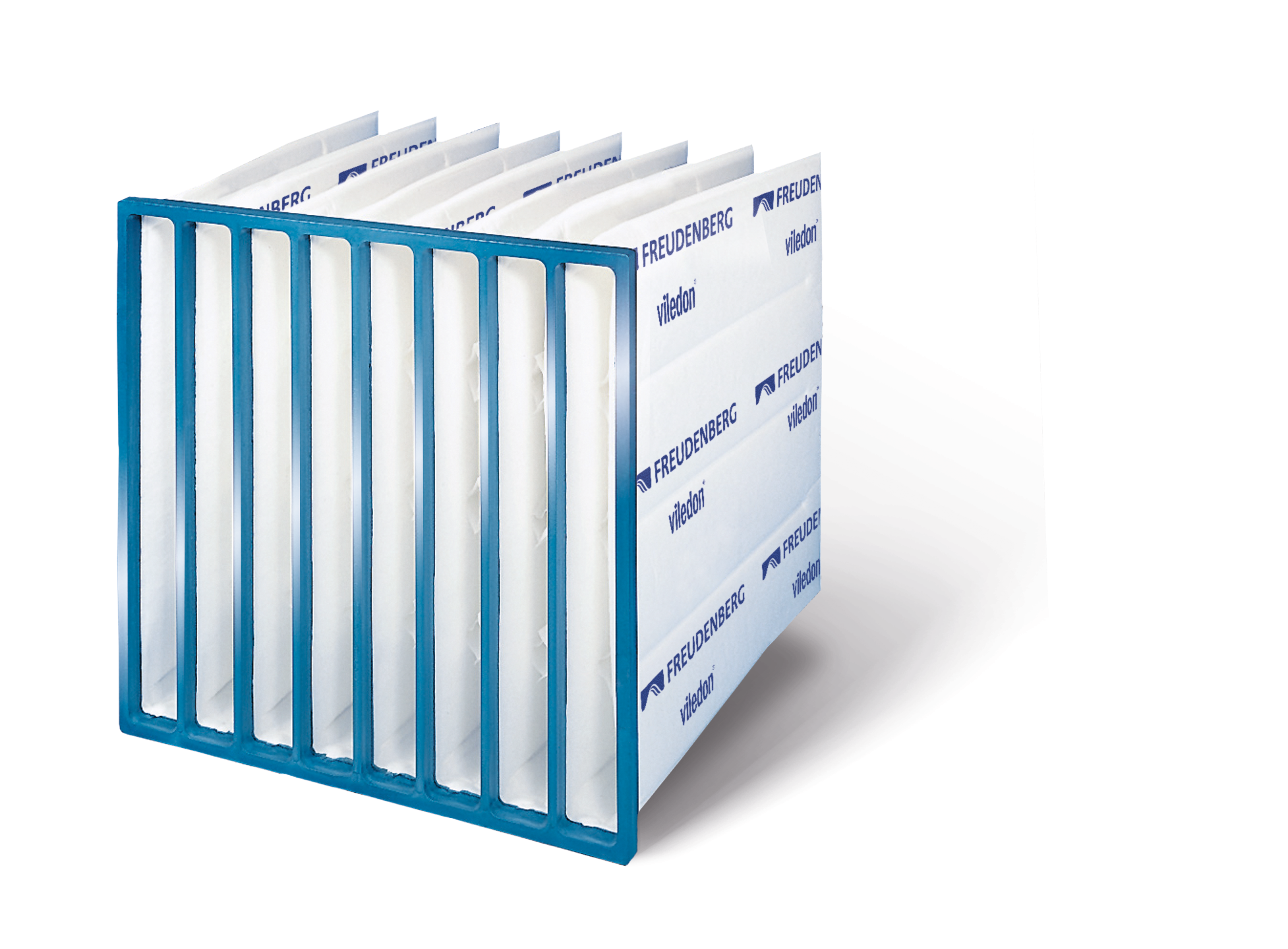

The T 60 sets the standard for pocket filter performance and high dust capacity. It's engineered to reliably stop aggressive, abrasive particles in demanding applications and extreme climatic conditions

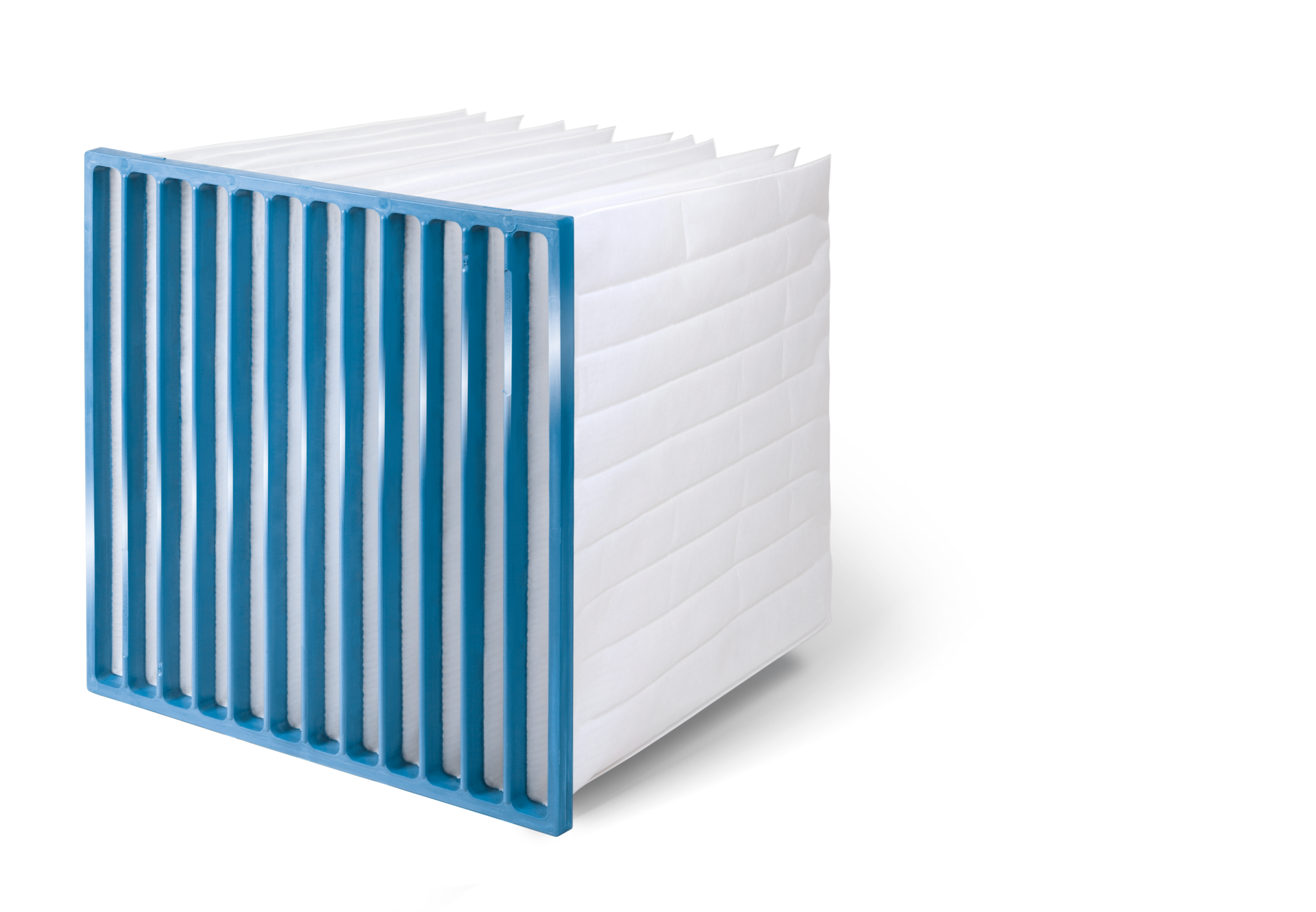

The T 90's, with extended surface area and tear resistant pockets, is engineered for high dust holding capacity, long service life, and the arrest of aggressive and abrasive particles under virtually all environmental conditions.

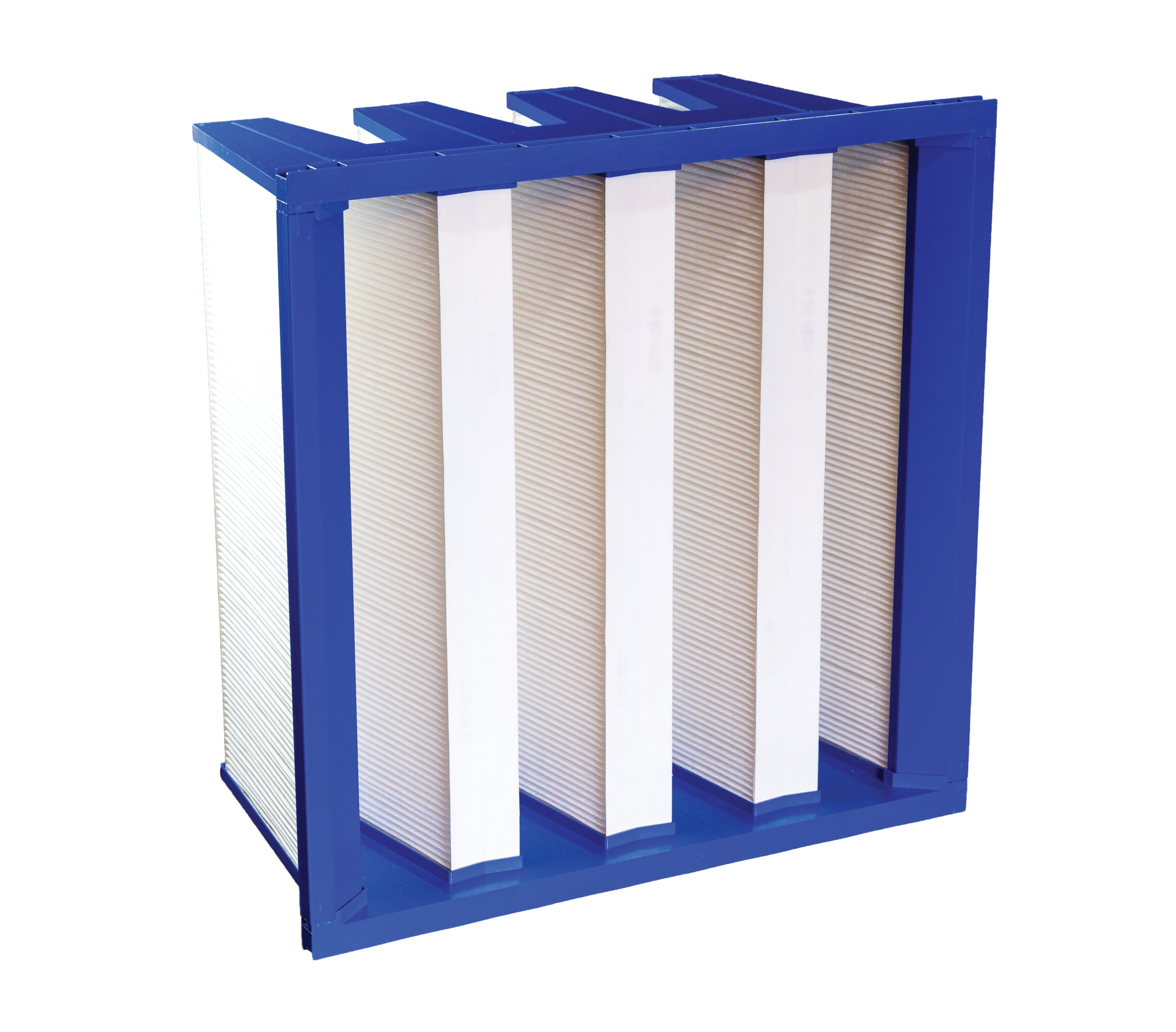

Viledon MV extended surface V-style filters are specifically designed for systems that have stringent requirements for clean air quality.

Offering high operational reliability and cost-efficiency they are ideally suited for intake air prefiltration at coastal, offshore, and other high humidity locations. Here they provide optimum protection of the subsequent filter stages keeping them dry thereby extending the operational lifetime.

A new generation of powerful, efficient, economic and resilient cassette filters. With it's deeper filter depth, this series offer high operational reliability and cost optimization, while increasing the efficiency of turbine performance.

Viledon MVPGT-21 cassette filters offer an extended filtration surface for an increased lifetime cycle. They are particularly well suited for intake air filtration of gas turbines and compressors, especially for onshore locations.