Smell something cheesy?

When food goes bad...

Several people have already fallen ill – but who or what is behind it? The criminals have already scattered in all directions. The only trace is a Roquefort cheese. At first, the investigators are groping in the dark, but one look under the microscope reveals the identity of the culprits in the supermarket: the team from the Federal Office of Consumer Protection and Food Safety have detected salmonella on the cheese.

The most important thing now is to protect the victims. Together with the manufacturer, customers are informed which products are affected and how they should behave in the event of illness. In supermarkets, across social networks and on the federal authority’s website, a call is put out to search for the contaminated cheese. Existing cheeses are removed from the range and consumers are asked to return their purchases. The head of the company then turns to those who have been affected and patiently answers questions from concerned customers via email and Facebook.

Expense factor recall

This level of transparency has been praised by foodwatch.de as exemplary in a comparable real case. In 2014, metal chips were found in biscuits made by Hans Freitag. Among other things, the head of the company addressed her customers directly on television. By dealing openly with the problem, consumers were protected from harm in the best possible way. Nevertheless, a recall of this kind places a heavy burden on manufacturers and markets. This particular production error cost Hans Freitag millions. Alongside the financial losses, consumer confidence in the company took a severe hit. So in our current scenario, the most important thing now is to carry out a detailed analysis to prevent food from spoiling again. Investigators set out to discover how the bacteria got onto the cheese.

On the trail of the perpetrators

Recalls of spoiled food are by no means the exception. In 2017, German supermarkets issued an average of three food warnings per week. Among other things, these were triggered by foreign bodies, incorrect labeling and, above all, microbiological contamination. This is also not the first time that salmonella has been detected by consumer protection experts. The bacteria can infect humans and animals alike and is therefore easily transmitted via food containing eggs, milk or meat.

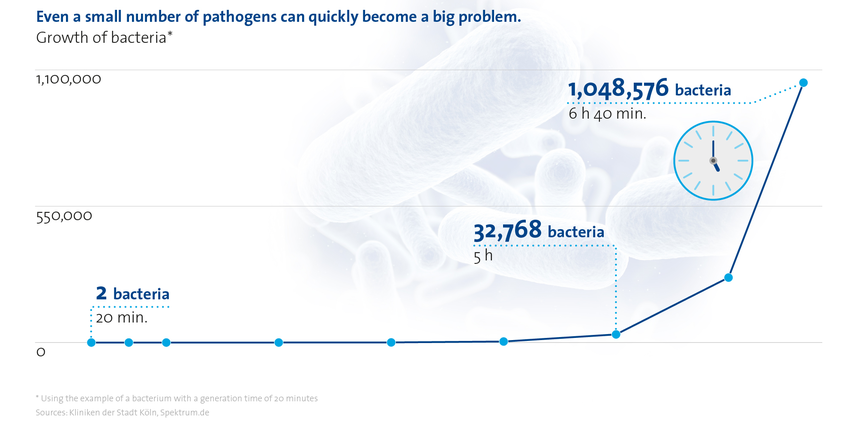

At temperatures between 20 and 40 degrees Celsius, salmonella can grow very quickly. The number of bacteria doubles within 20 minutes. After 40 minutes, the germ count has increased eightfold. Any interruption in the cold chain can lead to a drastic increase in salmonella and thus an imminent health hazard. In the case of the spoiled Roquefort, one of the refrigeration systems in the production plant in the small French village from which it originated failed for just a few hours.

Dangerous pathogens - air as contamination source

Even such short periods of time are more than enough for the pathogens to grow to dangerous numbers. In the case of typhoid fever or paratyphoid salmonella, the bacteria directly trigger these diseases. Without treatment, they can be fatal.

In our case, the investigators can breathe a sigh of relief: all they find on the cheese are enteritis salmonella, which cause diarrhea. As a rule, this sort of infection does not require antibiotic treatment. However, to avoid recontamination, the authorities recommend not storing food outside the refrigerator, not freezing it after thawing and heating animal food to 70 degrees Celsius for at least ten minutes before consumption. In this way, the culprits can be reliably removed from circulation. But the case is not over yet; there is even more in the air...

A bacterium with accomplices

Hidden on airborne dust particles, Clostridium-perfringens bacteria will attempt to settle on food. When they reach cheese, for example, they lead to a spoilage process in which carbon dioxide and hydrogen are formed, known as ‘late blowing’. If they enter the human digestive tract, they release endotoxins. As a result, spoiled food can lead to severe food poisoning. In the worst case, the pathogens can cause bowel blight, a frequently fatal condition.

Clostridia can be found almost everywhere in our environment. Their nitrogen-binding properties make the bacteria a potent fertilizer, which is why they are often used in agriculture. Their high resistance also makes it difficult to protect against contamination. Even at temperatures around 110 degrees Celsius, the pathogens are capable of surviving for up to an hour. Their anaerobic reproduction can also progress in airtight packaging. But how was the cheese spared from this pathogen in the current case?

Innovative friend and helper

Quite simply, the investigators had help. Before the germs reached the cheese, they were effectively captured by the air filtration system in the production hall. Reliable air filters are essential to protect consumers from germs of this nature. And this is precisely where the innovative filter systems manufactured and supplied by Freudenberg Filtration Technologies come into play.

Pocket and cassette filters, such as the MaxiPleat, offer a high dust holding capacity and great stability, which results in a long service life and maximum operational reliability. With their water-repellent coating, the filter media are manufactured using a patented thermal embossing process and prevent clostridia on dust particles from entering the production chain and spoiling food. To ensure clean air to cleanroom quality, HEPA filters can be installed downstream. With a separation efficiency of up to 99.9995 percent for 0.15 µm particles, they ensure maximum safety. This rebuilds consumer confidence in the manufacturer and prevents further recalls of spoiled food.

The investigators are now able to close the case. The Roquefort still has its distinctive mold but only the harmless variety. And even though some may find this famous cheese a little too pungent, at least the air filters have caught and eliminated the health pests. Leaving Roquefort lovers free to indulge their passion in complete safety.

Learn how Rügenwalder Mühle uses individual filtration solutions for flawless air hygiene.

Discover our solutions for the food and beverage industry.