Standards series DIN EN 1822 for HEPA filters

Introduced in 1998, the DIN EN 1822 filter standard was the first European standard to translate filtration knowledge into a classification system for HEPA filters. The introduction made it possible to assess the performance of the filters, which is achieved by checking the degree of separation and the absence of leaks. The DIN EN 1822 standard defines a method for testing filtration efficiency based on particle counting methods using a test aerosol. This means that even filters with very high collection efficiencies can be tested. Previous test methods were unable to do this due to inadequate detection limits. In contrast to EPA filters, which do not require leak testing, HEPA and ULPA filters are tested individually in accordance with DIN EN 1822 to determine filter performance. In this process, HEPA and ULPA filters are individually subjected to a leakage test. Some parts of DIN EN 1822 have now been replaced by EN ISO 29463.

Contents

1. The DIN EN 1822 standard and its filter classes

2. Areas of application for HEPA filters

3. What role does ISO 29463 play in EN 1822?

4. The five parts of the EN 1822 standard

5. How the EN1822 standard supports the containment of SARS-CoV-2

6. Viledon HEPA filters for effective protection

The DIN EN 1822 standard and its filter classes

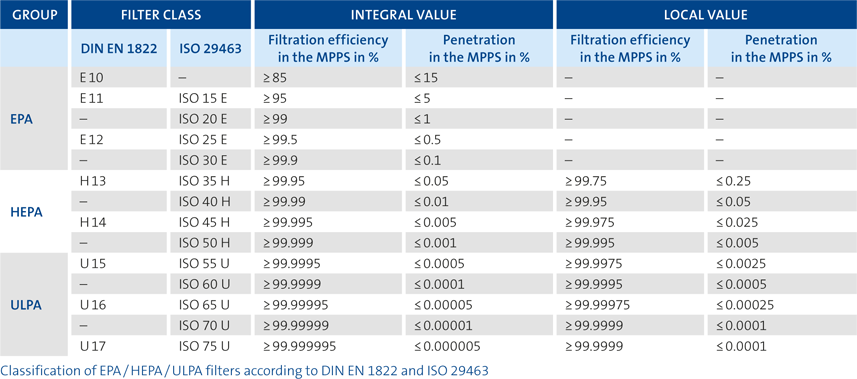

The DIN EN 1822 standard is a filter standard for HEPA filters and includes the following filter classes:

• EPA filter (Efficient Particulate Air filter)

• HEPA filter (High-Efficiency Particulate Air filter)

• ULPA filter (Ultra-Low Particulate Air filter)

Areas of application for HEPA filters

In situations where the highest demands are placed on air purity, the use of HEPA filters is essential. They are primarily used to separate aerosols, dusts and germs. HEPA filters play an important role above all as the last fine-mesh filter stage in sensitive areas. The focus here is on protection against contamination, for example by germs or airborne dust.

Particles such as germs, bacteria or soot are particularly relevant for EPA filters. Among other applications, they are used in food production, precision mechanics and the pharmaceutical industry. HEPA filters separate viruses, airborne dust or particles from combustion processes. Typical applications include operating rooms, intensive care units, electrical engineering and the food industry. ULPA filters filter suspended dust and are particularly important in clean rooms.

![[Translate to English (US):] Hospital air filter system [Translate to English (US):] Hospital air filter system](/media/_processed_/d/4/csm_krankenhaus-grafik-luftfilter-system_34c88a6ae2.jpg)

What role does ISO 29463 play in EN 1822?

EN 1822 provides the basis for the new ISO 29463. For the time being, EN 1822 remains valid but makes reference to certain parts of ISO 29463. As a consequence, air filters are classified according to EN 1822 Part 1 but tested according to ISO 29463 Parts 2-5. The international ISO 29463 standard is expected to replace EN 1822 eventually. Both ISO 29463 and EN 1822 are based on state-of-the-art particle counting methods.

ISO 29463 retains the EPA, HEPA and ULPA filter classifications familiar from DIN EN 1822. Evaluation continues to be carried out with the aid of particle separation at MPPS (Most Penetrating Particle Size). This refers to the size of the particles that are most difficult to capture. Defining the MPPS is the basis for being able to test filters. In contrast to EN 1822, ISO 29643 also specifies measurement with a photometer as a further method for testing the absence of leaks.

The five parts of the EN 1822 standard

EN 1822 has been revised several times since its introduction. In the current version, parts 2 to 5 have been replaced by ISO 29463 to ensure a worldwide standard for test methods. The most important difference between the old and new versions is the classification of the filter classes. Nevertheless, part 1 of the old EN 1822 remains in place.

Part 1: Classification, performance testing and labeling

The local collection efficiency (local value), together with the total collection efficiency (integral value) for the particle size with the highest separation efficiency (MPPS), forms the basis for the classification of HEPA filters. Because leak testing is not required for the classification of EPA filters, the specification of local values as leakage limits is not required here.

Part 2: Aerosol production, measuring equipment and particle counting statistics

Part 2 describes aerosol production and measuring equipment for testing high-efficiency filters and filter media in accordance with ISO 29463. It provides the statistical basis for particle counting methods with a small number of counted events.

Part 3: Testing flat filter media

The focus here is on defining the test procedures for testing the separation performance of flat filter media.

Part 4: Test method for determining the leakage of filter elements (scan method)

This part specifies the scan method test procedure as a reference method for determining filter element leakage. Part four also describes the oil thread leakage test and the photometer leakage test for HEPA filter classes ISO 35 H to ISO 45 H, as well as the leakage test with a solid PSL aerosol as additional normative methods.

Part 5: Test methods for filter elements

In the fifth part, a reference method must be determined to define the efficiency of the filters at the most difficult particle size to separate (MPPS). Guidelines are also given for the testing and classification of filters with an MPPS of less than 0.1 μm and for filters containing filter media with (charged) synthetic fibers.

How the EN1822 standard supports SARS-CoV-2 containment

Whether in offices, stores or restaurants, the risk of infection is high wherever large numbers of people are present for long periods of time. Indoor aerosols play a major role in the spread of SARS-CoV-2. Droplets are dispersed into the air through breathing, talking, coughing or sneezing. Mouth-nose protection and the safety distance of 1.5 meters mainly protect against the larger droplets that sink quickly to the ground. However, these measures cannot do anything against aerosols. Air purifiers with H14 HEPA filters according to DIN EN 1822 are the effective solution for removing virus-containing aerosols from indoor spaces. However, they should only be seen as a useful supplement to the hygiene measures that are still necessary,for example sufficient ventilation and should not replace them.

![[Translate to English (US):] Air filtration in public buildings [Translate to English (US):] Air filtration in public buildings](/media/images/Filtration_know-how/Protection_against_viruses/oeffentliche-gebaeude.jpg)

Viledon HEPA filters for effective protection

Viledon HEPA filters are ideally suited as the final filter stage in a multi-stage air filtration system for ultra-fine filtration. They guarantee effective protection for sensitive products and processes, for example in biotechnology, air-conditioning technology (operating rooms/intensive care units of hospitals, medical institutes, laboratories), the pharmaceutical industry and in the manufacture of foodstuffs and cosmetics. Viledon HEPA filters meet the highest standards of clean air and sterility. Effective prefiltration protects the high-quality filters, significantly extending their service life. All our filter elements are tested for filtration efficiency and freedom from leaks in accordance with EN 1822:2009 and are supplied with the relevant test certificate.

Contact us

![[Translate to English (US):] DIN EN 1822 filter standard [Translate to English (US):] DIN EN 1822 filter standard](/media/_processed_/0/3/csm_standards-and-certifications_c85a5794b4.jpg)