Optimized Turbine Performance in the Oil and Gas Industry – On and Offshore

High-performance filter concepts under all weather conditions

Fog, salt, spray, air pollution, and very high dust concentrations. The challenges faced by filters in Oil and gas production, which often takes place under especially difficult conditions, must be engineered to prevent corrosion and fouling, and increase overall service life of your equipment.

In oil and gas production, reliability and efficiency are top priorities. Overcome your challenges with the filter competence of Freudenberg in the area of oil and gas.

How?

- Tropics, arctic or desert – Freudenberg produces custom-tailored solutions for all climate conditions.

- Individually customized filter systems with an optimal combination of suitable filter types and filter classes.

- Extensive global experience in intake air filtration engineering solutions.

- Outstanding corrosion protection from engineered water-repellent filters with drainage effect.

- Balanced total cost of ownership (TCO) due to long filter lifetime.

- On-site technical support.

- After-sales service.

Learn more about intake air filtration for plants in the oil and gas industry.

Optimal protection against water and salt ingress

Learn more about Viledon hydroMaxx coalescer prefilters

Discover our products for the oil and gas industry.

Click on details for more information. Technical data and specific product features can be found in the product catalog.

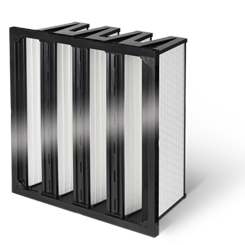

spiderMaxx stands for a generation of casette filters that sets standards in terms of stability and torsional rigidity thanks to the innovative filter frame design. Even under high load, the casette filters provide peak performance for efficient energy generation and minimal downtime in power plants.

The high mechanical strength of the material offers dimensional stability throughout operational lifetime, even when handling large air volumes.

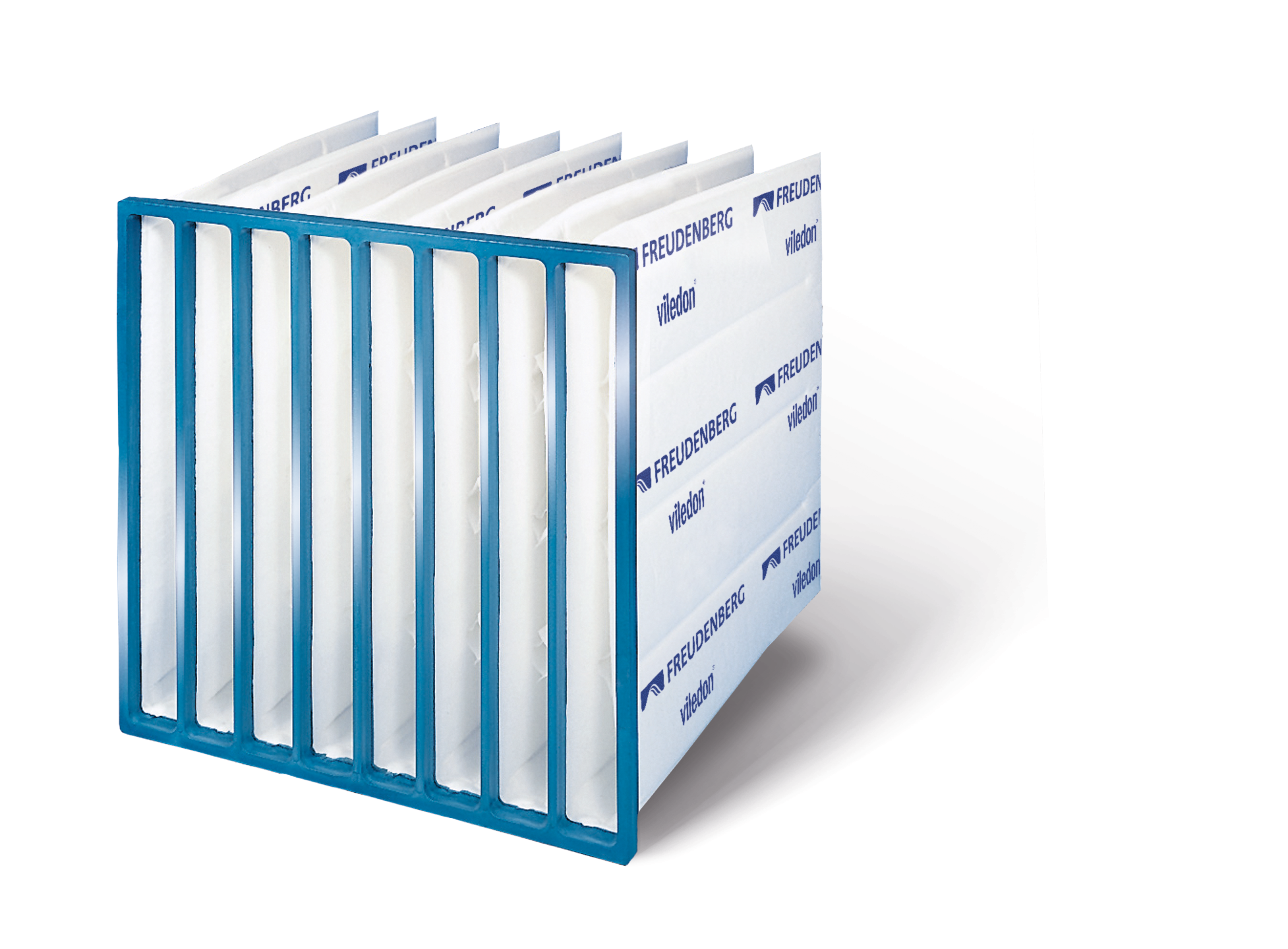

The T 60 sets the standard for pocket filter performance and high dust capacity. It's engineered to reliably stop aggressive, abrasive particles in demanding applications and extreme climatic conditions

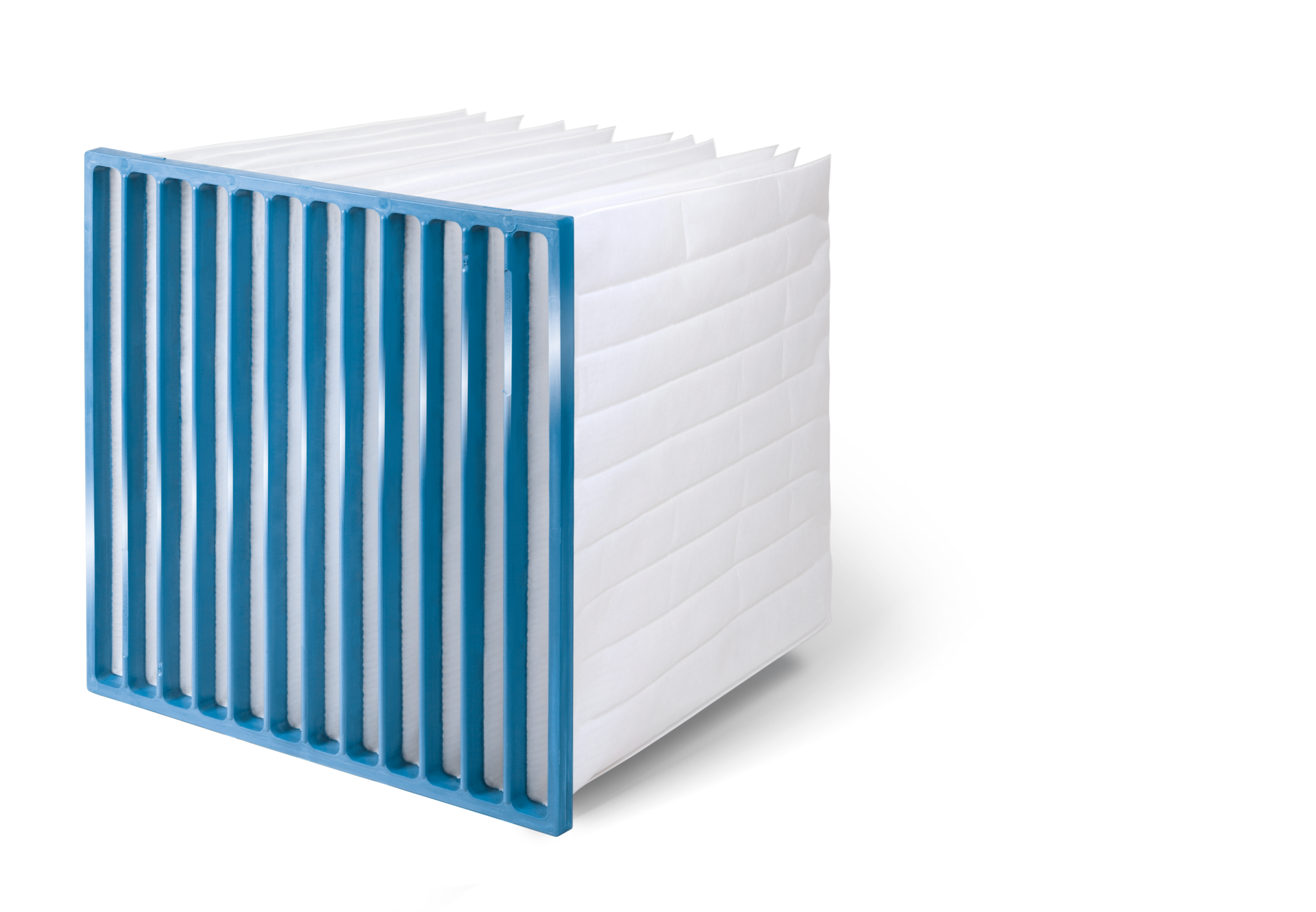

The T 90's, with extended surface area and tear resistant pockets, is engineered for high dust holding capacity, long service life, and the arrest of aggressive and abrasive particles under virtually all environmental conditions.

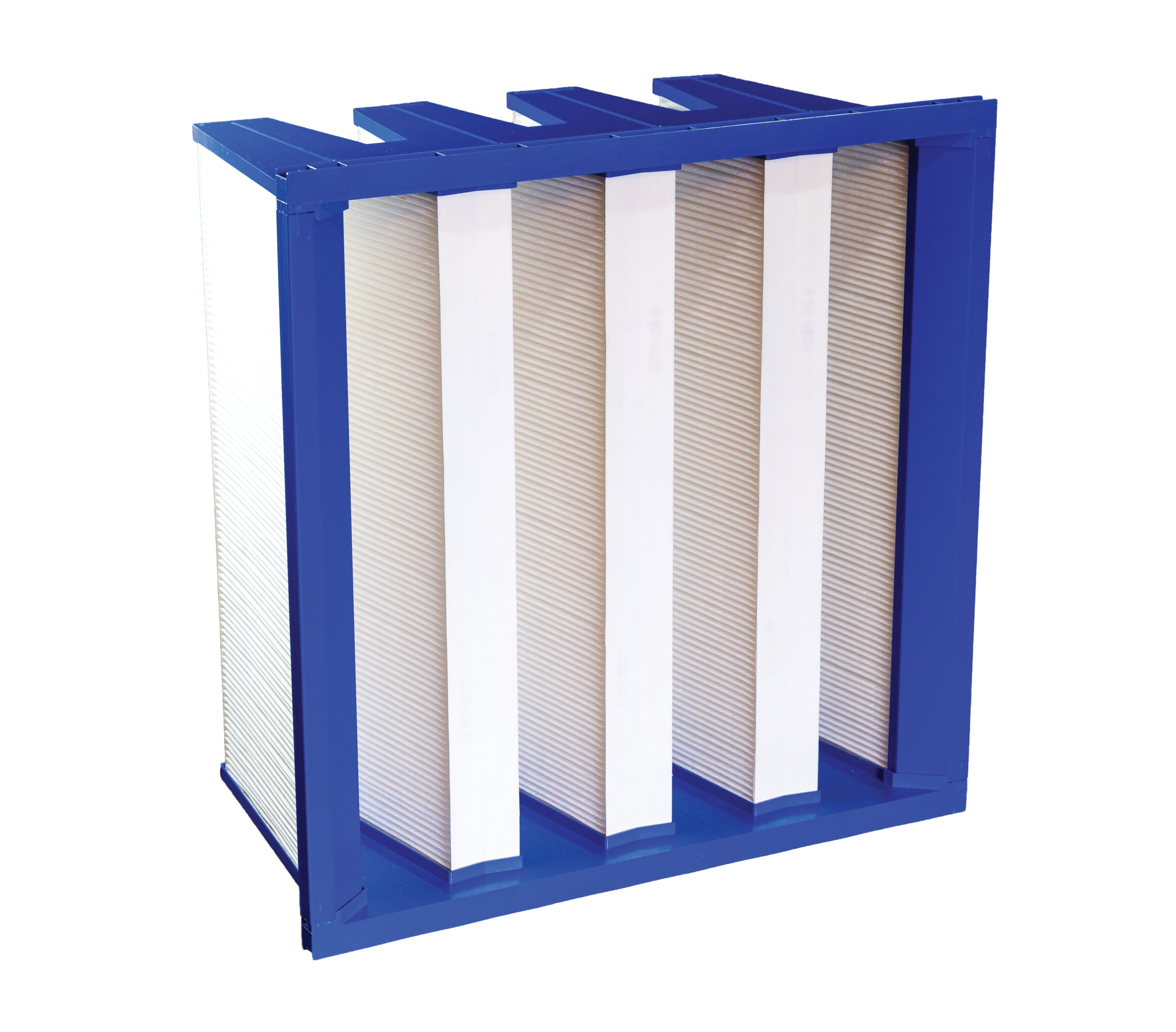

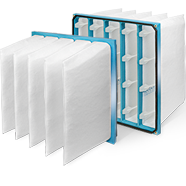

Viledon MV extended surface V-style filters are specifically designed for systems that have stringent requirements for clean air quality.

Offering high operational reliability and cost-efficiency they are ideally suited for intake air prefiltration at coastal, offshore, and other high humidity locations. Here they provide optimum protection of the subsequent filter stages keeping them dry thereby extending the operational lifetime.

A new generation of powerful, efficient, economic and resilient cassette filters. With it's deeper filter depth, this series offer high operational reliability and cost optimization, while increasing the efficiency of turbine performance.

Viledon MVPGT-21 cassette filters offer an extended filtration surface for an increased lifetime cycle. They are particularly well suited for intake air filtration of gas turbines and compressors, especially for onshore locations.