Discover our filtration solutions for the painting industry

Benefit from Freudenberg expertise now

Filters + Service + Consulting = Viledon filterCair

Optimize your painting process with Viledon filterCair modules

Viledon filterCair is a customer-tailored service package to meet your individual filtration and painting needs. It consists of a comprehensive range of filters plus services plus problem-specific air quality consulting by our Viledon filterCair specialists at guaranteed fixed costs.

Your painting process is subjected to a full analysis to determine the cause of paint damage. The focus lies on optimization of your process with regard to errors and return rates, increasing the system availability and lowering your operating costs.

With our Viledon filterCair modules, we offer you a comprehensive selection of problem-specific services and air quality consulting solutions that can be individually combined.

Your advantages at a glance

- Comprehensive, problem-specific service packages

- Ability to combine individual service modules

- Status analysis and detailed recommendations for action by our Viledon filterCair experts

- Comprehensive, interactive and audit-relevant measurement reports

- Individual on-site advice

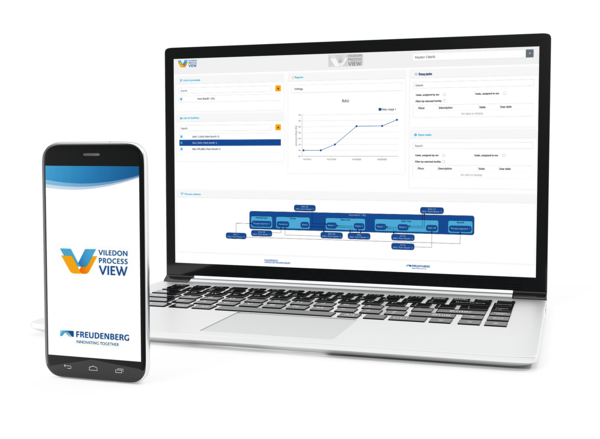

Digital filter monitoring with Viledon Process View

The innovative data management system offers a comprehensive solution for monitoring and managing filter systems, simply through smartphones and QR codes.

How efficient is your filtration system?

Find the optimal filter solution for your plant with e.FFECT based on ISO 16890

Standardized systems for intake air filtration are frequently inefficient and do not make full use of their potential for optimization. The more specifically filter systems are customized to the respective ambient conditions and plant requirements, the greater performance and reliability they achieve.

With e.FFECT, the electronic Freudenberg Filter Efficiency Calculation Tool, calculating the optimal filter solution is extremely simple. The local ambient conditions and specific process requirements enter directly into the calculation. This simplifies the selection of the best filter concept for your needs.

Benefit from our specialized expertise in industrial painting.

Select and request detailed information.

Discover our products for industrial painting.

Click on details for more information. Technical data and specific product features can be found in the product catalog.

High-quality material structure and a high shape stability for a maximum efficiency in paint mist separation.

The technically stable and engineered design of the MaxiPleat series offers continuous reliable operation for even the most extreme conditions. With a hydrophobic coating, a patented thermal embossing process, and leak-proof casting, these filters provide dependability with cost efficiency.

Progressively structured, with the density of the fiber layers increasing towards the clean air side. This ensures an optimum in terms of defined filter performance and dust holding capacity, coupled with a low pressure drop.

Robust in sustained use, with high operational dependability and reliability even in the face of extreme moisture and wet conditions. These filters enable energy-efficient operation which translates to cost savings and a reduction in CO2 emissions.

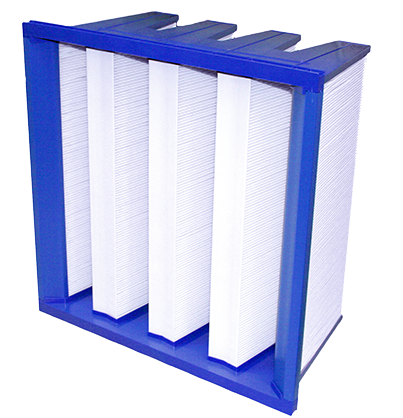

Viledon MV extended surface V-style filters have been specifically designed for systems that have stringent requirements for clean air quality. Featuring 100% synthetic and hydrophobic filter media, it is the ideal choice for HVAC systems, or, any air handling system which requires resiliency in operation.

The best choice for air filtration at temperatures above 100°C up to a maximum of 385 °C. The silicone-free filter elements are suited for extreme and stringent requirements for air purity, process dependability, all with cost-efficiency.

Offering high operational reliability and cost-efficiency they are ideally suited for intake air prefiltration at coastal, offshore, and other high humidity locations. Here they provide optimum protection of the subsequent filter stages keeping them dry thereby extending the operational lifetime.

Efficient filtration of paint mist in the painting process. Maximum process reliability through long lifetime and high paint storage capacity.